Lead Lustre Cut Top Flat Bottom Gallery

"Cut Top Flat Bottom" does not represent a Lead lustre decor, but rather a different method of production.

Lead Lustre pieces were blown into paste moulds (a cast iron mold that is lined with wetted cork or sawdust so that when the molten glass is blown into it there is a steam cushion created between the glass and the iron). This allows the glass to be rotated while it is blown, resulting in a piece that has no mould lines or seems.

Lead Lustre pieces were blown into paste moulds (a cast iron mold that is lined with wetted cork or sawdust so that when the molten glass is blown into it there is a steam cushion created between the glass and the iron). This allows the glass to be rotated while it is blown, resulting in a piece that has no mould lines or seems.

This describes regular Lead Lustre production and culminates when the still hot pieces are "stuck up" by their bottoms on a metal rod for final shaping, finishing and, once separated from the metal rod, grinding down of the rough area where it was connected to the bottom of the piece - producing a pontil mark. The rim was also finished at this time.

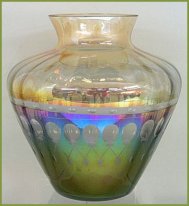

While the "Cut Top Flat Bottom" pieces were also blown into a mould, they were not "stuck up" and have a flat bottom without a pontil mark. Additionally the tops were simply cut off, not finished like regular production.

See the difference in bottoms:

|

|

These pieces are all cased (two layers of glass), as are most regular production pieces, and have typical Lead Lustre & Free Hand decors, but with different color combinations. The most frequently found shape for these pieces is "Shape #771", from Imperial's Lustre Iridescent Ware line (illustrated by the "balloons" vase at the top of this page).

Click each photo to enlarge and see descriptions.

Error